We are pleased to announce that we were successful in domestic development of plant-based polyurethane foam with a biomass of 50% or higher, named “ECOLOCEL® BEH” (hereinafter called “ECOLOCEL®”).

“ECOLOCELⓇ” is a name of INOAC’s domestic biomass polyurethane foam composed of over 50% of plant-based raw materials. This polyurethane foam is composed of over 50% of inedible plant-based raw materials. Despite the high biomass composition rate, we were successful in maintaining physical properties equal to products using oil-based raw materials.

Features of ECOLOCELⓇ

Features of ECOLOCELⓇ

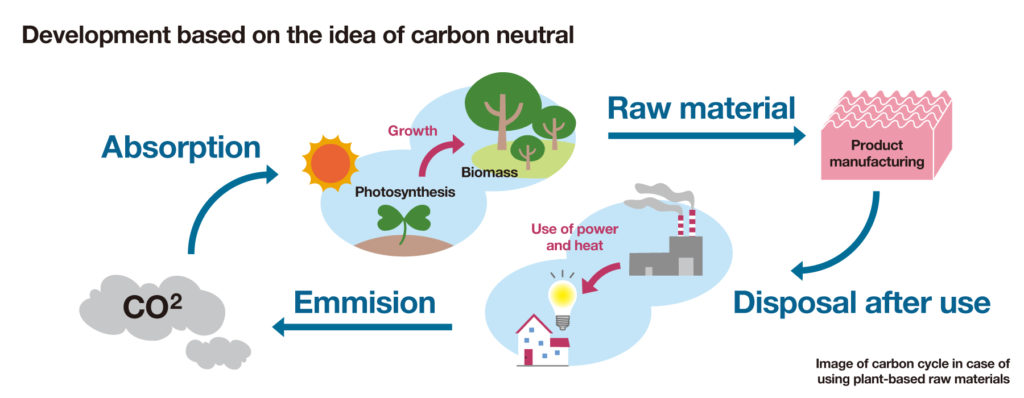

- Reduced CO2 emissions due to carbon neutrality

- Less reliance on fossil resources

- Low odor (little odor of charactersitc in plant-based raw materials)

- Mechanical properties equal to products with oil-based raw materials

- Wide range of applications (kitchen cleaner, mattress, pillow, clothing pad, etc.)

Stories behind the development of ECOLOCELⓇ

Today, companies are faced with the crucial challenge of using limited resources effectively to contribute to building a sustainable society.

In recent years, marine pollution caused by microplastics and waste treatment have become social issues of a global scale. Manufacturers, therefore, face strong expectations to address these problems.

INOAC has been engaged in responding to such environmental issues for over 40 years by attempting to develop plant-based materials. From early 2000, we started to take earnest steps to turn those materials into products.

Today, companies are faced with the crucial challenge of using limited resources effectively to contribute to building a sustainable society.

In recent years, marine pollution caused by microplastics and waste treatment have become social issues of a global scale. Manufacturers, therefore, face strong expectations to address these problems.

INOAC has been engaged in responding to such environmental issues for over 40 years by attempting to develop plant-based materials. From early 2000, we started to take earnest steps to turn those materials into products.

Since the plant-based products were weaker than oil-based products, the quality was unstable. These presented significant hurdles to developing commercial products, which was an issue that continued for many years. However, we have been developing products based on the idea of

“carbon neutral” and our pride as a leading company of polymer materials.

The road to the development of polyurethane foam containing 50% or more of plant-based raw materials was extremely difficult, but after repeated trial and error of compounding and foaming tests, we finally achieved successful development.

The road to the development of polyurethane foam containing 50% or more of plant-based raw materials was extremely difficult, but after repeated trial and error of compounding and foaming tests, we finally achieved successful development.

Inquiry to ECOLOCELⓇ

Foam Products Division, INOAC Corporation

e-Mail:[email protected]

Original publication on inoac.co.jp