INDUSTRIES

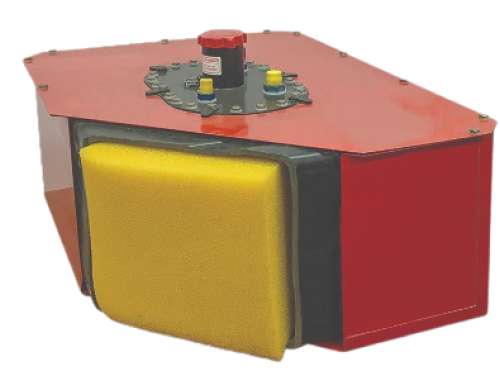

Military - Explosion Suppressant Foams

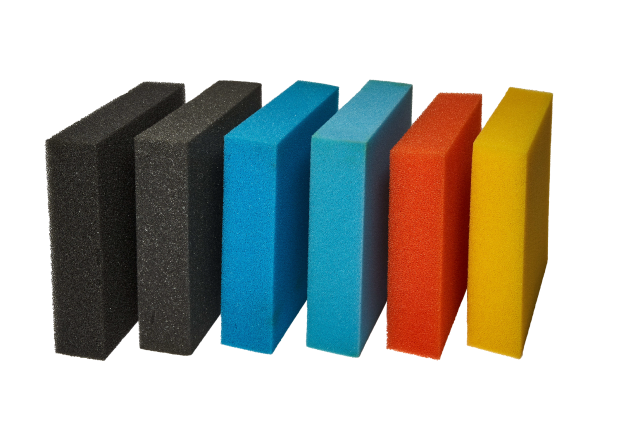

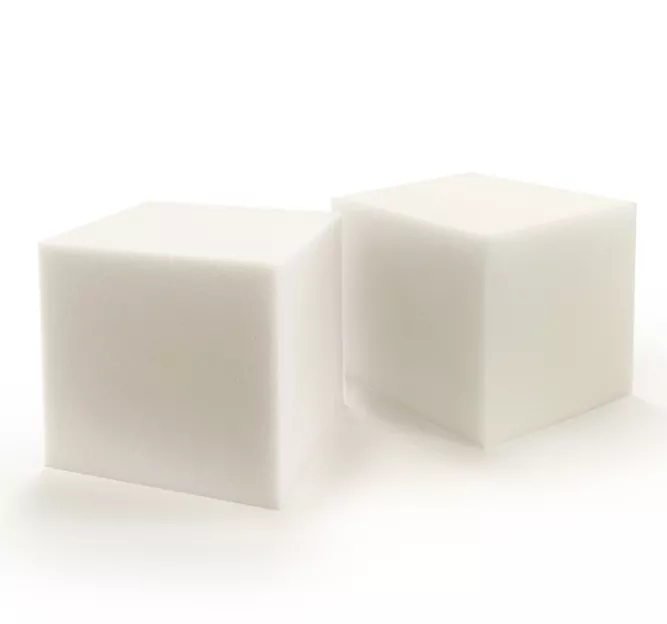

Reticulated polyurethane foam

Our reticulated polyurethane foams for explosion suppression and surge/noise mitigation are unique, environmentally friendly materials for use in the fuel tanks of aircraft, boats, military vehicles, competition and emergency vehicles, automobiles, and trucks – virtually any vehicle where the possibility of fuel tank explosion exists, or where surge/noise mitigation is required. Explosion Suppressant Foams (ESF) are ideal for use in fuel storage tanks and containers, both stationary and portable.