PRODUCT

Mattress Foams

We spend 25% of our lives sleeping. The regenerative processes that take place during sleep are extremely impactful on health and well-being.

We have developed leading foam technology for mattresses and bedding. Our engineered foams offer a variety of standard foam grades as well as customized solutions.

RESTING COMFORT

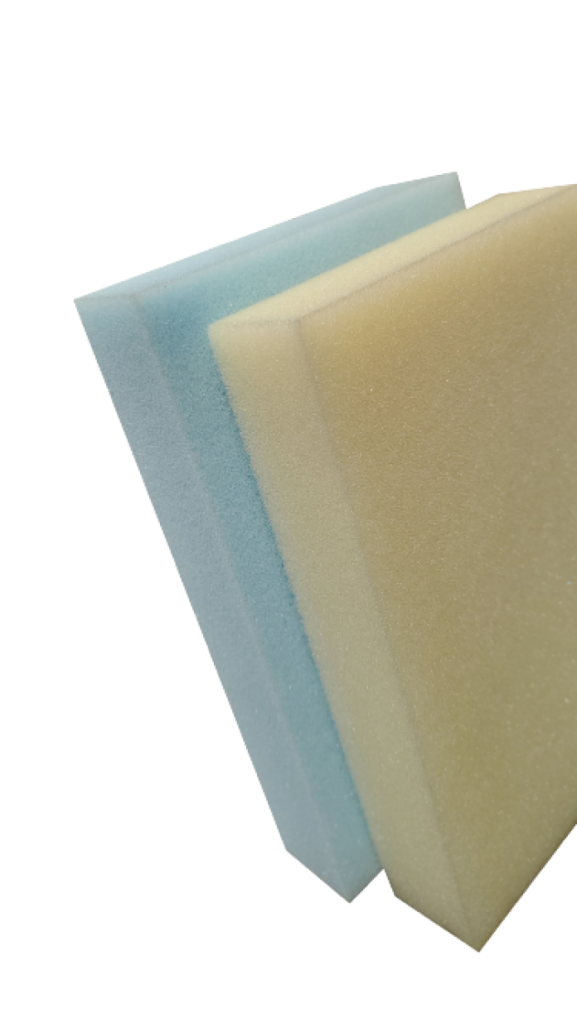

High Airflow Foam

The High Airflow Foam (HAF) is designed for the efficient movement of air and humidity while placed in a mattress core construction. This movement or dissipation of air and humidity allows for a more restorative sleep experience. The HAF product can be used as a transition layer beneath the top layer or as a top layer foam.

FOAM FEATURES

- Air flow is greater than conventional urethanes

- Available in ether slab stock polyurethane

- Available in two standard colors – blue and yellow

- Excellent compressions set and humid aging characteristics

- Provided as buns, rolls, sheets and compressed sheets

IDEAL FOR:

- Medical bedding

- Residential bedding

- Wheel chair seats

- Medical positioners

| Type | AirFlow CFM | Density lb./ft3 | IFD | Comp Sets 50/90% | Humid Aging Comp sets |

|---|---|---|---|---|---|

| HAF – 26 | 4.0 min | 1.40 – 1.60 | 20-30 | <10% loss | <10% loss |

| HAF – 36 | 4.0 min | 1.40 – 1.60 | 30-40 | <10% loss | <10% loss |

Resting Comfort

Relax Foam

FOAM FEATURES

- Ether latex like foam

- Air flow is greater than conventional urethanes.

- High resiliency

- Available in two standard colors

- Provided as buns, rolls, sheets and compressed sheets

IDEAL FOR:

- Medical bedding

- Residential bedding

- Wheelchair seats

- Medical positioners

| Type | AirFlow CFM | Density lb./ft3 | "IFD 4” 25% Deflection lbs/50si(N)" | Color |

|---|---|---|---|---|

| 2710 MHRT1 | 2.0 | 2.5 - 3.0 | 8 - 14 | Tan |

| 3020 MHRCO | 2.0 | 2.8 - 3.5 | 18 - 25 | Charcoal |

COMPARATIVE DATA

| Relax | Regular Foam | Latex | |

|---|---|---|---|

| Resiliency | 61% | 39% | 52% |

| Support Factor | 2.90 | 1.93 | 2.45 |

Resiliency is a % return after impact. This is also an indicator of improved motion transfer.

Support factor is the foams ability to support force at various compressions.

Custom quality engineered designs can be arranged. Contact Us.

NEWS & EVENTS

Latest Updates

Woodbridge INOAC Technical Products Launches new website

INOAC introduces ECOLOCELⓇ plant-based polyurethane foam